An unforgettable practical phase: Gühring student travels Birmingham

Jonas Burth studies industrial engineering at Gühring and Ravensburg Cooperative State University (DHBW). But that’s not all: During his fifth practical placement, he had the opportunity to spend five weeks working at our British office in Birmingham.

Ready for a new chapter

A total of 34 apprentices and students recently successfully completed their training at Gühring in Albstadt and Laiz. The examination certificates and diplomas were presented at a small celebration – including seven prizes and two commendations.

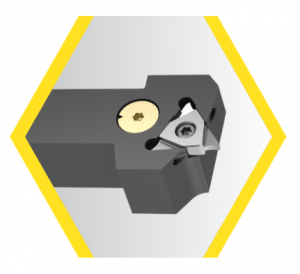

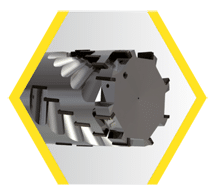

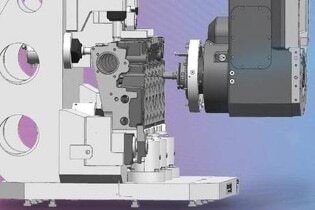

Tool shank and clamping chuck: Perfect concentricity thanks to a suitable clamping surface

The interaction between the tool shank and clamping chuck is important for perfect concentricity. In this article, we will introduce you to the different clamping surfaces HA, HB and HE and explain the consequences of choosing the wrong clamping surface.

1 milling cutter, 5 success stories: This is how the RF 100 Sharp impresses

The RF 100 Sharp solid carbide high-performance milling cutter is currently the sharpest milling cutter on the market and Gühring is therefore racking up success stories form satisfied customers around the world. We have now compiled five such success stories for you.

Grooving tools in practice: one workpiece, five solutions

The goal of many machinists is to process a complete component with as few tools as possible. Especially with complex parts, several working steps are necessary – and each one has its challenges. Our turning and grooving tools are ready to take them on.

“Licence to mill”: Bond car milled from solid material

Bringing together the three best products makes the perfect process. Gühring and Blaser have combined an MQL oil with a solid carbide corner radii milling cutter and a tool holder. And showcase the advantages that collaborative engineering can yield.

Gühring becomes a member of VDWF

Gühring is now a member of the Association of German Tool and Mould Makers. By becoming a member of the strongest trade association in the sector, we aim to further expand our commitment in this field and seek to exchange ideas on level ground.

6 reasons why your production needs a tool management system

Searching for tools takes an incredible amount of time. All tools have their place in our tool management cabinets. Tidy, locked, with controlled dispensing. In this article, you will find out how to revolutionise your production and save costs.

Four times more threads with hard milling

Tools for punching sheet metal have to withstand a lot. Hago Feinwerktechnik GmbH therefore uses materials of up to 66 HRC in its own toolmaking facilities. Here, two Gühring tools not only impress with low wear, but also with considerable cost savings.

One software, 11 problem solutions: GTMS in everyday work

Gühring Tool Management Software (GTMS) is a tailor-made product for your manufacturing process. But what can GTMS do for you and what problems can be solved in your day-to-day work? This is what we show you here month after month. Discover now!

Tool life up, costs down: three tools for higher parameters

Enjoy longer tool lives and save money at the same time: Hennecke from Sankt Augustin is managing to do that together with Gühring. Three SC highlight products show why the machine and system manufacturer relies almost exclusively on Gühring for milling.

We find the mistake with process data analysis

Not every problem can be solved with a quick glance into the machine. However, in the event of deeper problems, Gühring offers a holistic production analysis using GTMS. Everything you need to know about the new “process data analysis” service!

Transparency through digitisation and networking

Gühring offers a strong tool for optimal clarity in production: the “Gühring Machine Control Center” (GMCC). This tool enables direct machine connection and thus creates transparency. This is how you benefit from the networking of your production!

G-Mold μ milling cutter – for high-precision requirements in mould making

The demands that mould makers place on cutting tools are high – after all, they are responsible for more than 90 % of the product quality. Gühring meets these requirements with a brand new milling cutter range designed specifically for mould making.

The new StepPower: circular holes by hand

Conventional handheld drills require a lot of force which can result in non-circular holes or annoying burrs at the hole exit. The new StepPower twist drill from Gühring masters these challenges. Its unique design ensures precise, circular holes.